Experiments in Eco-Processing

Blog 2018 February

February 1, 2018

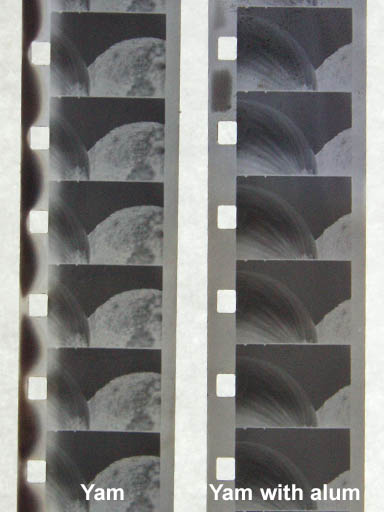

I recently read that avocado skins boiled down give off a nice deep red. I boiled four avocado skins in two litres of water and then processed for 15 minutes at 23°C. The film was thin. The guacamole was tasty!

This process is similar to the eggplant developer. I like the fact that I only need to boil the skins of avocados for this developer, but that means I have a lot of avocado meat left over and a person can only eat so many avocados...or can they?

To conserve on avocados, I through I would try reusing the avocado skins by boiling them again in fresh water. Perhaps if I increased the developing time from 15 minutes to 20 minutes, I could compensate for what would probably be a weaker "tea." This idea did not work, as the film was even thinner but it did have a nice pink hue. What this means is that, I absolutely need to use new ingredients every time I brew a tea to maintain some sort of consistency in my experiments. Can I borrow somebody's copy of “101 Avocado Recipes I Have Loved” I am going to have a lot of avocados on my hands.

Avocado test #3 was done with two fresh avocados boiled in two litres and processed at 24°C for 15 minutes. Also, another tint discovery - this was a relatively fast tint done in 23 hours.

February 5, 2018

Onion

I am out of avocados for the moment, so it is onto red onions, some people call them purple onions, maybe because they look red on the outside skins but purple on the inside.

A few articles I have been reading have mentioned there are more polyphenols in yellow onions than red onions, despite this I am decided to experiment with red onions because I wanted to explore more red tints. There are still about 168mg/100g of phenolic compounds in Red Onions. I also found out the outer layers of onions contain more polyphenols than the inner layers. The onion tea changed colour after I added the washing soda and vitamin C.

Onion pH levels seemed to be good The green test strip was the tea, the blue strip is after washing soda and vitamin C have been added.

I was very happy with Test #1 and proceed to try an onion eco-reversal.

The first onion reversal did not really work... nor did the second... or the third.

According to my calculations with the onion developer, the reversal should have worked, but it didn't...why?

What I have noticed, with the onion, is that when I empty the water between the clearing wash (or stop bath) between Dev1 and the Bleach the water is very purple, too purple. This means that I am losing a lot of emulsion in the wash… but why? It seems that the water between these two steps is too hot.

A typical reversal might look like this:

| Step | Time | Temperature |

|---|---|---|

| Water wash | 3 min. | 22°C |

| Dev 1 | 18 min. | 24°C |

| Water wash | 3 min. | 32°C Purple water, too hoo! |

| Eco-bleach | 10 min. | 38°C |

| Water wash | 3 min. | 31°C This temperature may also be too hot! |

| Expose to light | 150 sec. | |

| Dev 2 | 8 min. | 24°C |

| Water wash | 3 min. | 22°C |

| Fix | 6 min. | 21°C |

| Final Wash | 10 min. | 22°C |

In the January blog, I wrote about using the water washes to warm up the film, so that when it is time for the bleach step the jump in temperature is not such as shock to the film (this is to prevent reticulation). However, if the water wash is too hot, perhaps I am burning the film, so that by the time the bleach interacts with it, it is already burnt. Then, when Dev 2 begins, the image is already burned off, so all that is left after Dev 2 is the dense film.

When I was conducting eco-reversal experiments with the kale my wash temperatures were more in the 26°C to 27°C range and the film turned out nicely. Going forth I will keep the washes in this range and see what transpires.

Today I was reminded...

"Processing is a process and each step is a part of the whole."

February 9, 2018

Back to Avocados

I stopped into my local camera store today on an unrelated matter but ended up chatting with one of the employees who used to process their own film. We got to taking about the flecks on my kale footage (I am like a grandma I always have pictures of my experiments to show interested and not so interested parties). He thought that the specs in the kale were not caused by an unstable bleach but by organic material in the developer. I thought about it, that could make sense, but then I disagreed because the specs didn’t occur in any of my developer tests only in the reversal. Unless of course the eco-bleach can activate the small organic particles in the kale tea, but I don’t think so. He did get me thinking about straining my tea a bit better than with a sieve.

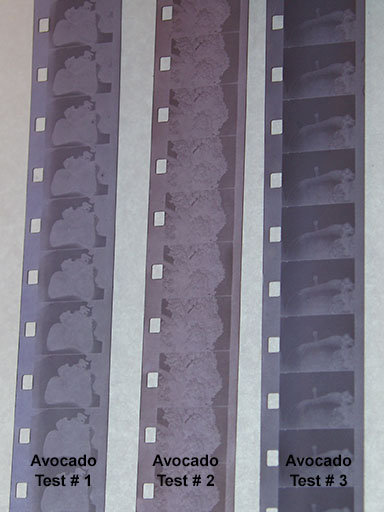

Today, I decided to strain my avocado tea, with a sieve and paper towel! This eliminated all of the floating avocado bits and gave me a nice pure tea to work with. I also decided to boil the pit of the avocado with the skins and made a fun discovery!

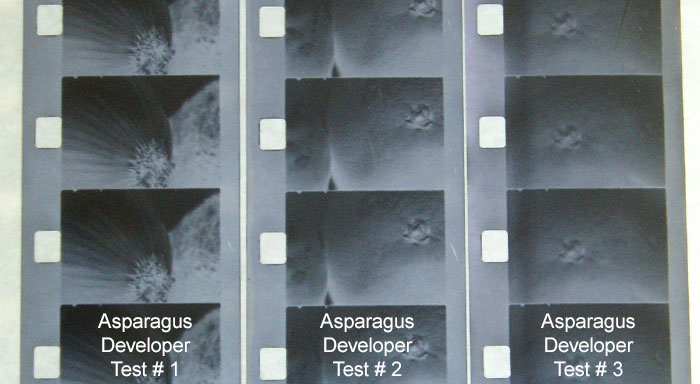

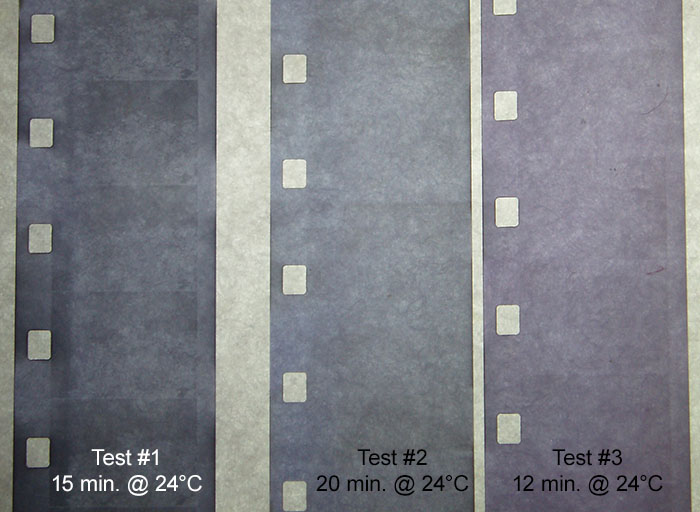

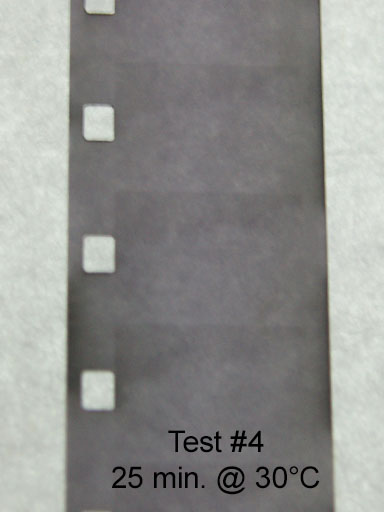

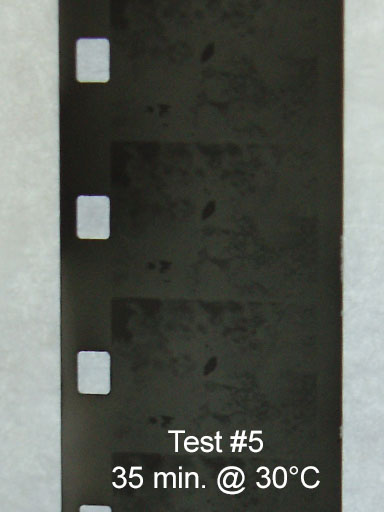

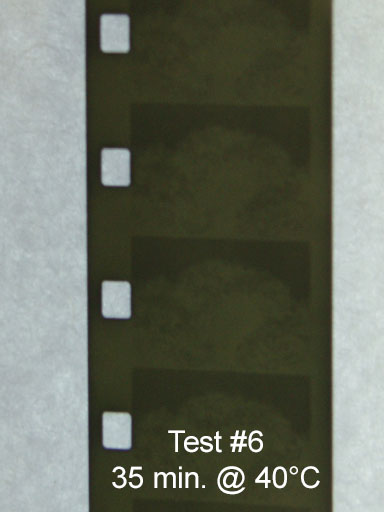

Below are some examples of the avocado developer tests from this week.

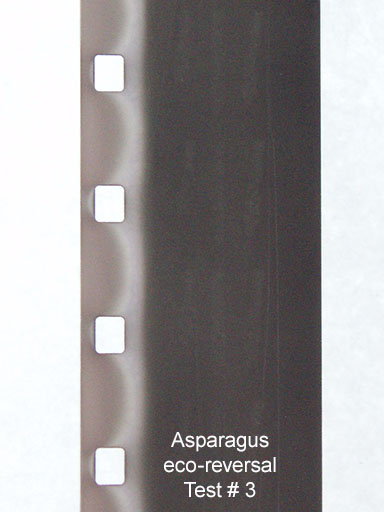

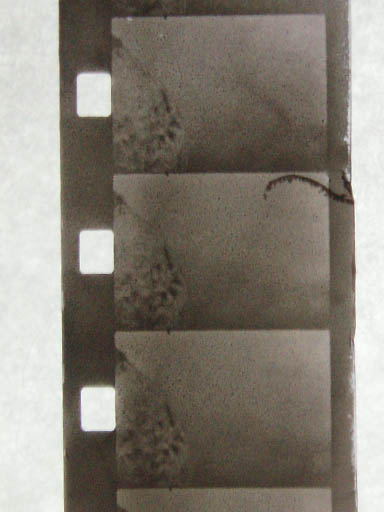

And the avocado eco-reversal.

The reason why I am happy about this image (as dense as it is) is that it displays the latent edge numbers on the side of the film, the frames are also visible. Unfortunately, all I shot was a white background for this part of the film. It would have been nice to have an image but sometimes this is what happens. I must remember in the future to always film "something" at least for a reference image.

The reason why I am happy about this image (as dense as it is) is that it displays the latent edge numbers on the side of the film, the frames are also visible. Unfortunately, all I shot was a white background for this part of the film. It would have been nice to have an image but sometimes this is what happens. I must remember in the future to always film "something" at least for a reference image.

February 16, 2018

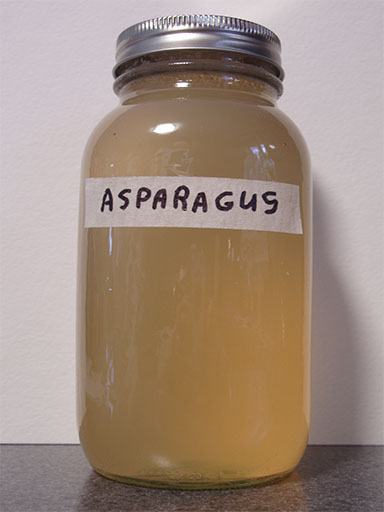

Asparagus Waxing

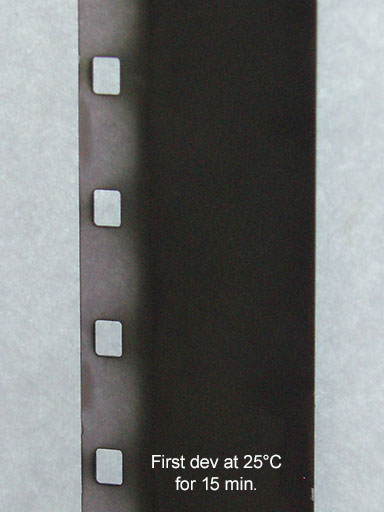

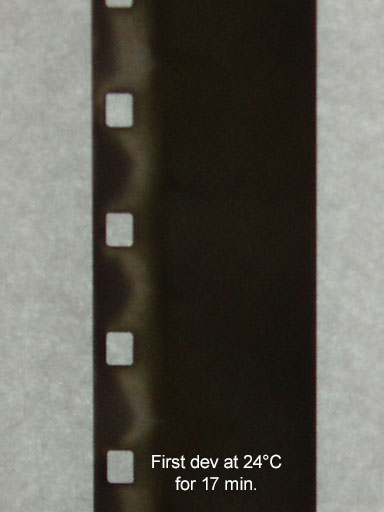

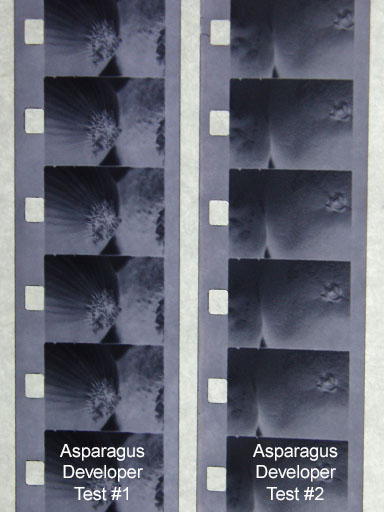

I had some 3 month old asparagus tea in mason jars and decided to use it. I developed two tests from two different jars, that had slight colour variations. Both films turned out beautifully! Good darks, highlights shadows, almost as good as caffenol.

I thought I was ready for the reversal with the asparagus but something when wrong.

1. It could have been the developer. I had to make a new batch, I used frozen asparagus from this autumn. Perhaps the chemistry was compromised by freezing the asparagus.

2. I could be the water wash step between Dev 1 and the Bleach. I did the rinse (keeping the temperature around 26°C) but the spent water came back purple loaded with emulsion. The only solution I see around this is to go right from Dev 1 to the bleach without the water wash in between.

Just to make sure it was the frozen asparagus I did another quick developer test. Developer test #3.

Despite good readings....

...most of the emulsion is washed away in the water rinse between the developer stage and the bleach stage...

...after the Second Dev this is what is left - a dense mess. Asparagus eco-reversal Test # 1

Boiling frozen asparagus

...most of the emulsion is washed away in the water rinse between the developer stage and the bleach stage...

But after all of that…

Perhaps all asparagus are not created equal?

I decide to develop more of the asparagus footage I shot and followed the above steps exactly. Same temperature, what I hope to be the same agitation, I even omitted the stop/wash bath between Dev 1 and the bleach and this is what I got…

The only thing that has changed is the asparagus. Perhaps it is because it is coming all the way from South America and is traveling too far. Could it be the fixer?

The only thing that has changed is the asparagus. Perhaps it is because it is coming all the way from South America and is traveling too far. Could it be the fixer?

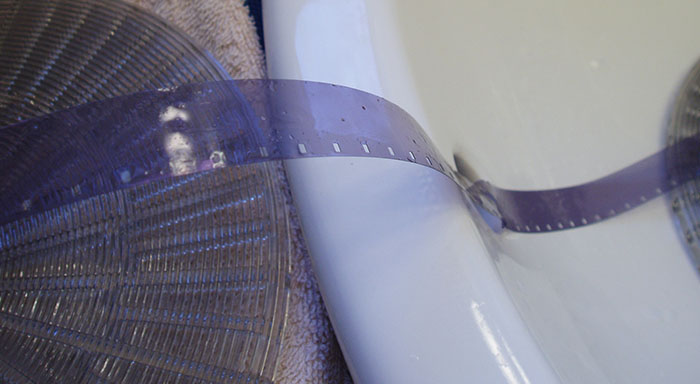

A way to test to see if the fixer is still active is to take an undeveloped, unexposed piece of film and fix it for the require amount of time (in this case 6 minutes). If the film comes out completely clear the fixer is still good. I had 16mm tri-x in the fridge for just an occasion.

The lighting in this photo is a little deceiving but the film is generally clear. The fixer is not the problem. The fixer is still good.

I gave the asparagus eco-reversal one more shot...being consistent as possible.

Still not very good results when it comes to the reversal process.

Sigh…all asparagus are not created equal.

The asparagus experiments were frustrating because I thought I has an amazing developer but I could not get the eco-reversal to work. I should be happy with this discovery, but I am a bit bummed out. It makes sense to have these results and I suspected that seasonality, freshness, and quality could affect the results of the developer. As mentioned before, there are no failures but discoveries that informs the next steps. All parts of the discovery process are important, but it is still a bit of a let down when you thought you had a very consistent plant and then things turn out to be different.

Do scientists get disheartened when something they thought was going to workout goes a different way? Perhaps the best thing to do is, sit with this for a bit, learn, and carry on.

I even found several articles with huge discrepancies in the phenolic amounts in asparagus - some had 141mg/100g another 75mg/100g but the majority averaged around 29mg/100g.

But maybe...it is not asparagus, maybe it is the reversal process?

I have been using the same eco-reversal process for the caffenol, blueberries, and kale. Could it be that the eco-reversal process is not working as well or is dependent or reactive with the eco-developer?

I decided to give the asparagus developer one more try...

Asparagus Developer Test #4 is perfect (excepted that I loaded it in the tank wrong, which accounts for the line on the sprocket-less side of the film).

It looks like I have to refine the eco-reversal process a bit more.

Maybe, all asparagus are created equal after all.

February 23, 2018

Dragon Fruit

Dragon Fruit is also called a pitahaya, but who wants to eat a pitahaya when you can eat a dragon. This tropical fruit has vibrant pink skin, that I hoped would translate to a decent developer or tint - it did neither very well, but what a grand beautiful cactus tree! It has nocturnal flowers (pollinated by bats and moths I suspect). I would love be hiking and happen upon a Dragon Fruit Tree one day.

For this experiment I stuck with one recipe:

1 Litre Dragon Fruit Tea

80g of washing soda

20g of vitamin C

Increasing the temperature and duration until I got a semi-decent developer.

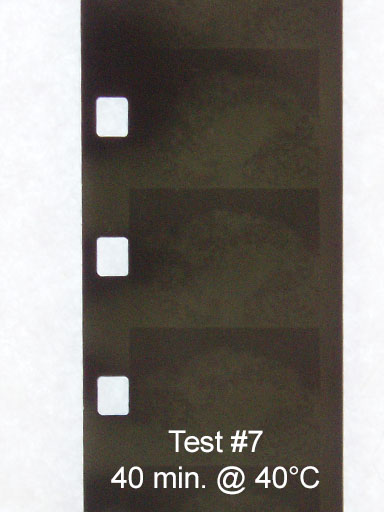

Tests #6 and #7 produced some nice green tinting, despite the fact that the developer was more yellow.

I opted not to try a reversal for this fruit because the results were…unremarkable.

It was challenging locating the average number of polyphenols for this fruit, as most of the data was for the dried powder derived from the skin of the Dragon Fruit, but it seemed to be around 150mg/100g.

In my quest to find an average on how many polyphenols were in Dragon Fruit I came across the term phytochemistry which is the study of chemicals derived from plants. Phytochemistry is used in herbal medicine but scientists also use it in cosmetic and drug research. Some of the information I am finding is public, but some articles are only available for purchase or rent (one article said I could rent nn article for a week for six dollars).

Chemistry is fascinating. I took it in high school but was never that jazzed by it, perhaps because I wasn’t cooking or into plants back then. Now, I love it. I love how everything is connected, works together, and how you can break everything down into the most microscopic of parts. Chemistry is cool.

February 28, 2018

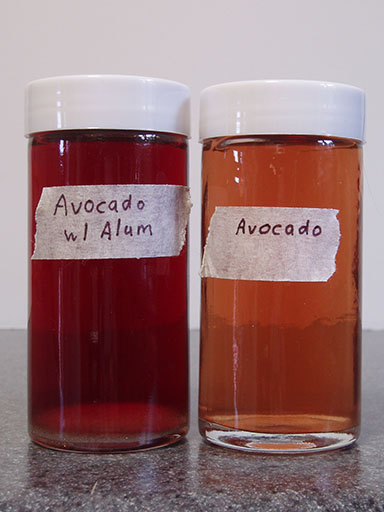

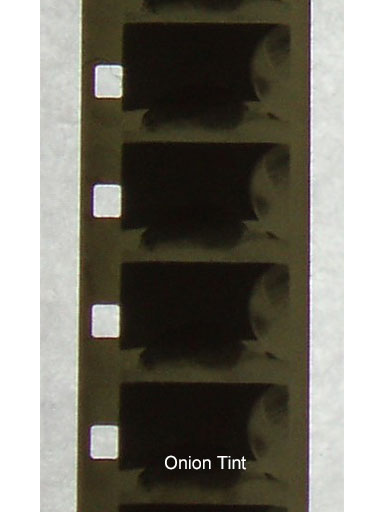

Yam

Yams are not sweet potatoes. The differences between these tubers is that yams are generally starchier and drier, and their meat is a pale white/yellow compared to the meat of the sweet potato which is usually orange but can also be purple or yellowish or reddish. It is though that yams originated from areas in Africa and Asia while sweet potatoes came from areas in Central and South America. Yams are related to lilies (monocots) and sweet potatoes are related to morning glories.

Yam

Cutting

Juicing

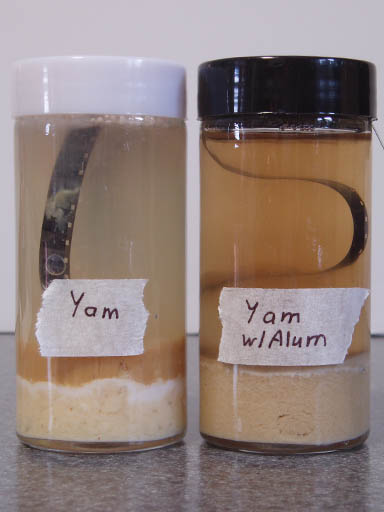

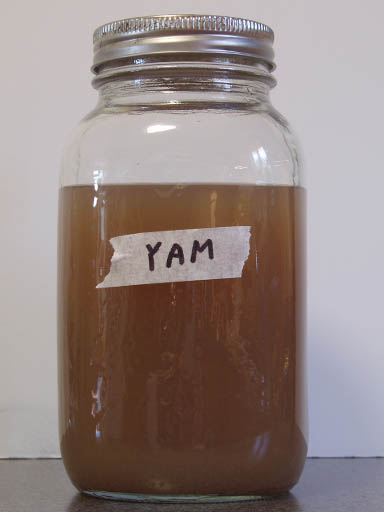

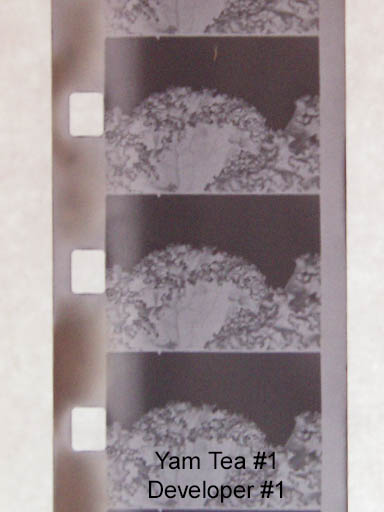

Juicing Yams produced Yam Tea #1

I also used it for a tint but it produced a lot of sediment.

Then I took the pulp from the juicer...

boiled it...

till I got this...

and then strained it, to get...

...this.

Yam Tea #2 had less sediment.

A bit blotchy...

...but generally a very nice developer.

On to reversal!

Mixed up the Yam-ol using Yam Tea #1

Good pH levels before and after.

Uh oh!!

Omitting the wash stage between Dev 1 and the eco-reversal bleach created an extreme reaction.

The lomo tank bubbled over.

The eco-reversal bleach continued to bubble after it was drained from the lomo tank.

Yam Reversal #1

Did not produce stellar results.

Yam Reversal #2 was made with Yam recipe #2 (from the pulp).

This time there was not an extreme reaction and the film turned out well...for the most part.

Sometimes the developer worked very well.

I like this organic eyelash looking piece from the yam that ended up on the film.

Sometimes the developer didn't work very well but it sure provided interesting results.

Yam tint results after 6 days, a very subtle tint.